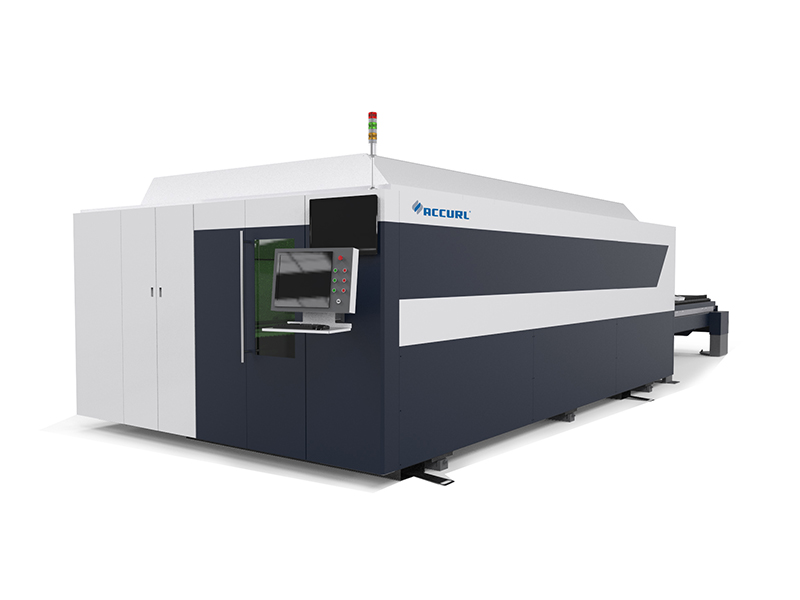

CNC Cutting Machine

A top quality CNC cutting machine includes a cutting table that covers the region bounded by a amount of four feet and a width of eight feet. CNC Cutting Monmouthshire are designed for satisfactorily a standard 4 x 8 plate of metal, wood, plastic, glass, or stone. A table that lacks an adequate length or width can make it essential for the operator to repeatedly reposition the plate. Operators of the CNC cutting machine refer to such repositioning as indexing.

A good basic CNC cutting machine does both plasma and oxyfuel cutting. Refinements on a simple cutting machine may provide it with the ability to perform other functions, functions such as:

-spotting holes for drilling

-drilling aluminum

-cutting a shape in the sides or end of tubing

-routing wooden shapes

Other modifications on a CNC cutting machine may be directed at installation of the gear for laser or water jet cutting.

Selecting a CNC cutting machine will be primarily determined by the nature of cutting which will be performed by the device operator. For a few operations, it will be essential to do only straight cutting. For other operations, the cutting machine must perform bevel cutting. Bevel cutting allows the operator to trim, reduce, shave, and pare the material in the plate.

Both forms of cutting will subject the CNC cutting machine to a good amount of deterioration. The manufacturer therefore needs to buy a machine with adequate customer support. Such support should include the availability of spare parts. An absence of spare parts could require that the electronics of the CNC cutting machine undergo a retrofitting.

A dependence on retrofitting would deprive the operator of important production time. The need for retrofitting would diminish the number of goods that could be sold to the consumer. The necessity for retrofitting results in a decrease in how much time that the operator will be spending at the CNC cutting machine. This is why the availability of spare parts for a malfunctioning CNC cutting machine remains one of many two chief concerns of the maker. Another prime concern is the size of the cutting table.

The operator of a CNC cutting machine that must spend a large percent of time indexing will not have much time to invest on the specific cutting. Hence, the maker will have much less product. Fewer products from the manufacturing unit result in fewer products on the shelf. Consequently, the need for operators to invest time indexing can prove a detriment to the business's bottom line. A good sales volume reflects the well-planned purchase of a CNC cutting machine.